Product Details:

Payment & Shipping Terms:

|

| Products: | Boat Titanium Parts | Material: | Gr2 Or Gr5 |

|---|---|---|---|

| Surface Treatment: | Plating, Polishing, Sandblasting, And Original | Processing: | CNC Machining, Polishing, Cutting |

| Application: | Seafaring, Ship, Boat, Vessel | Tolerance: | 0.01mm-0.05mm |

| Size: | Customized Design Drawing | Color: | Silver, Burn Blue, Shiny Color |

| Advantage: | Light Weight, High Strength, Anti - Corrosion | OEM: | YES |

High Strength Titanium Precision Parts Anti Corrosion , OEM Ship Accessories

Product description:

| Products | Material | Size | Color | MOQ | Processing | Delivery | Package |

| Titanium hinge | Titanium alloy | Customized | Silver | 200pcs | CNC machining | 20 workdays | Poly-bag |

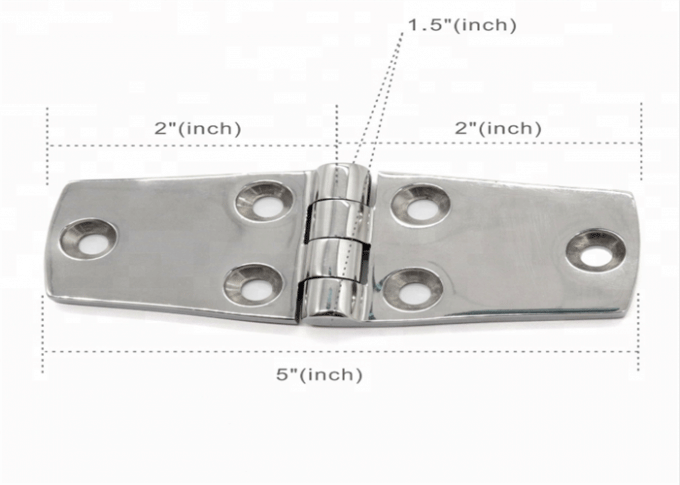

Titanium hinge size details as below just for reference.

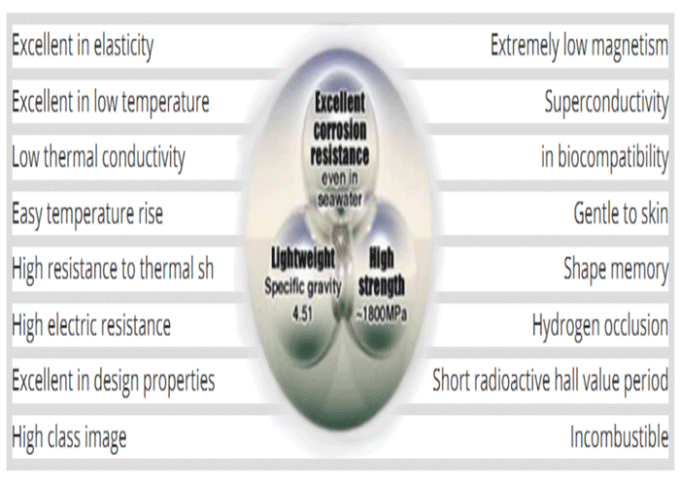

Typically in the past, marine hardware parts have been made from stainless steel. However, stainless steel is prone to rust and crevice corrosion caused by exposure to a saltwater environment. The high iron content (typically 60%-70%) is what causes stainless steel to corrode away. Titanium’s low iron content (0.3%) means that it is corrosion free. Titanium hardware parts on the deck of a boat will last indefinitely without ever needing to be polished to prevent damage from the natural marine environment.

As any boat owner knows, reducing weight is always an ongoing battle. Titanium weighs about half as much as stainless steel, yet its alloys can be over 3 times as strong. Titanium’s strength-to-weight ratio is one of its most famous benefits. Parts made from titanium can be made with less material and yet maintain a sufficient amount of strength to perform their function.

Advantages:

Titanium metal and its alloys are desirable materials for ship hulls and other structures because of their high strength, light weight and corrosion-resistance.

If constructed in titanium, Navy ships would have lighter weight for the same size—allowing for a bigger payload—and virtually no corrosion.

But because titanium costs up to nine times more than steel and is technically difficult and expensive to manufacture into marine vessel hulls, it has been avoided by the shipbuilding industry.

But perhaps not for much longer

What kind of parts is better to place by Titanium?

We made thousand of titanium parts in the ship field, In our experience, Below type of parts may help you coming out good advice.

Shackles, Stanchions, bolts, nuts, washer, screw, pipe fittings, tubing, propeller shafts,

hardware, top fittings, ground tackle, U-bolts, pins, eyebolts, rods and studs.

Related product recommendation:

Could possible make customized parts by Titanium?

Yes! Titanium own the Best performance in the ship field.

If there any interested to place other metal by Titanium, Just send us details or drawing, We can make it perfectly by Titanium material!

Email Us: inquiry.titanium@shapedparts.com

Tel: +86-755-28535736

CNC Titanium Precision Parts Body Post Mounts For SCX10 AXIAL 4WD CAR

Customized Titanium Machining Services For Strict Precision Gr2 Gr5 Parts

M6 Titanium Precision Parts Rear Wheel Spacers Washer For Fast Racing Daytona

Burn Blue CNC Titanium Parts Auto Shift Knob For Automobile Truck / Racing

CNC TC4 Titanium Clevis Kits 5/8" Birdcage Clevis With Right Hand Thread

Threaded Eye Bolt CNC Titanium Parts Gr2 Gr5 M8 X 35 Din444 Resistant Corrosion

Desert Racer Custom Titanium Machining Suspension Upper Arms Left And Right

Caliber Racing Oversized Titanium Parts Honda Motor Titanium Foot Pegs Fits

Auto Racing Head Custom Titanium Machining Motorized Bicycle Engine Parts